Fusion3 F410

|

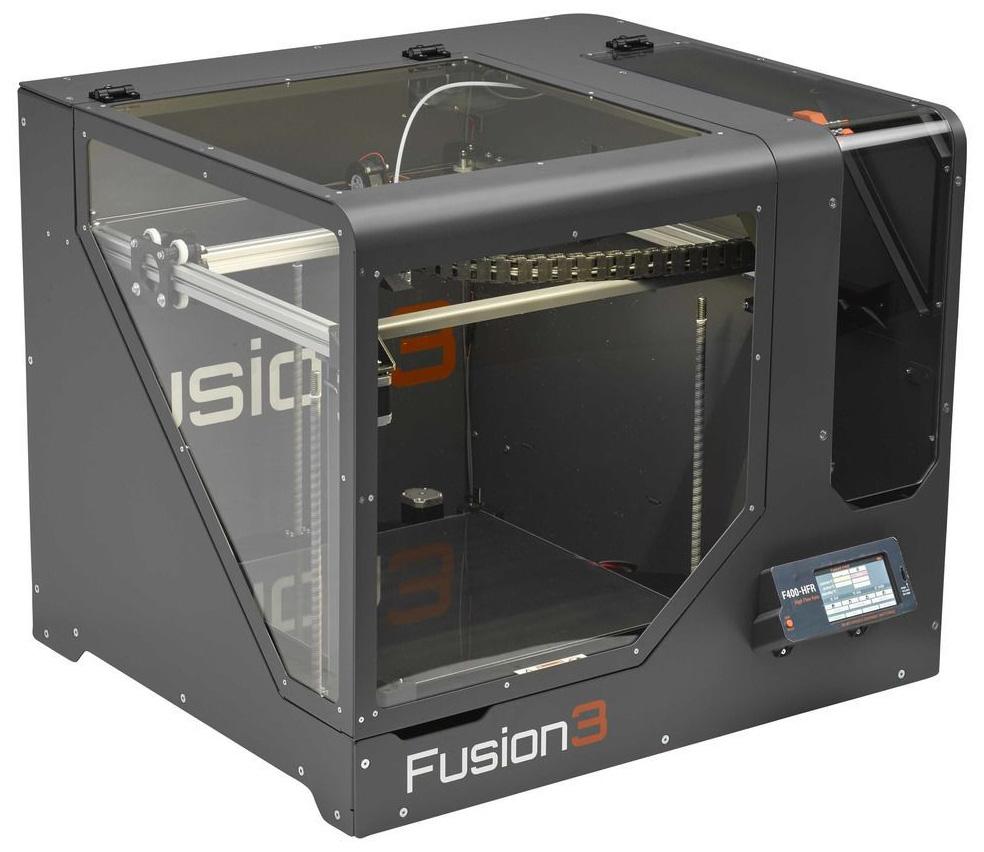

Fusion3 F410

|

|

|---|---|

|

|

| Status: Active with limitations, contact the lab manager | |

Superusers

- Reese Snook (rsnook@terpmail.umd.edu)

- Ivan Penskiy (ipenskiy@umd.edu)

Overview

Fusion3 F410 is a professional-grade Fused Filament Fabrication (FFF) 3D printer designed for high-speed, high-quality printing of large parts. It features a substantial build volume within a fully enclosed chamber that maintains a stable environment, ideal for printing high-temperature, engineering-grade materials. The printer utilizes interchangeable E3D Volcano print heads with hardened steel nozzles in 0.4mm, 0.6mm, and 0.8mm sizes, allowing users to balance print speed and detail according to project requirements. Its 2.0 extruder includes filament detection and cleaning features, reducing the risk of print failures due to jams or contamination. Additional features include automatic conductive bed leveling, a heated glass print surface, and remote management capabilities via Ethernet or optional Wi-Fi.

Location

E.A. Fernandez IDEA Factory (Bldg. 228), room 3119.3D printer specifications

| Max print volume (W × D × H) | 355 x 355 x 315 mm (14 x 14 x 12.4 inch) |

| Layer height | 0.02 mm - 0.3 mm standard layer height: 0.2mm |

| Supported materials | – common: PLA, ABS, TPU, PETG, ASA – uncommon: HIPS, PC, TPE, NYLON – with supervisor approval: PP, PVA, composite materials |

| Maximum print head temperature | 300 °C |

| Maximum heated bed temperature | 140 °C |

| Accepted file types | .obj, .3mf, .stl |

Important documents and useful links

- Official user manual

- Basics of FDM printing guide by All3DP

- Download F3Slic3r slicing software

- Slic3r manual

Reservation

Fusion3 F410 must be reserved before using. The reservation is done using the Google calendar. Users will be able to reserve the equipment personally after attending the RAL lab orientation and then following the steps below to gain access to the equipment.

Video demonstration

The following videos demonstrate capabilities and the some aspects of operating the Fusion3 F410 printer:Important reminders and safety

- Some parts of the printer get very hot during operation and take a while to cool down. Be careful when removing the printed parts or doing work inside the printer.

- Make sure to log the print and the amount of material used.

Designs can be made in any software capable of saving models in STL format (e.g. Onshape, AutoCad, SolidWorks, ProE, etc.). The on site computer station is meant for operating lab equipment only. Do not work on your CAD models here, your files can be brought over on a flash drive or wireless method.

Remember to set the appropriate tolerances in your STL files: tolerances should be smaller than the smallest feature in your design. Don't make tolerances much smaller than 3D printer resolution. Also, be mindful that small tolerances produce larger files.

- Guide to tolerancing for 3D prints

- Design for 3D printing guide by All3DP

- Visual troubleshooting guide

3D printing conceptual guides

- 3D printer anatomy, youtube video

- 3D printing basics, youtube video

TBD

TBD

TBD

Shutting down procedures

- Ensure that no active print jobs are running.

- Flip the main the power switch located at the lower right back.

Gaining access to equipment

Read the printer's user manual and contact the lab manager (ipenskiy@umd.edu).